|

Lockformer Vulcan plasma cutting systems are renowed for their unrivaled structural integrity and smoothness of operation. Better quality underneath is reflected in a better quality cut on the surface of the material. The Vulcan 1000 set the standard for compact, cost-effective plasma cutting systems. With the introduction of the enhanced 1000C, the best just got better-and even more productive.... |

Vulcan 1000C Plasma Cutting Systems

Strength & Stability

With its fixture welded 75mm x 75mm steel tubing framework, the Vulcan 1000C could be made by Formtek machinery Beijing. The superior structural integrity of the frame which is 45% stronger than any other system at this price point- enables the Vulcan 1000C to achieve unrivaled levels of strength, stability and accuracy. We believe the heavy-duty construction is essential , without it , the highest levels of job quality and repeatability cannot be achieved.

Power & Precision

At the heart of the Vulcan1000C you'll find a sealed DC servo motor of the highest quality. No inferior stepper motors here. The y-axis DC servo motor is linked to a 50mm diameter steel shaft that drives both sides of the machine simultaneously. Combined with a 3" diameter x 128' long y-axis guidance rail and a Hiwin linear x-axis bearing and way, the Vulcan 1000C achieves unsurpassed levels of stability, accuracy and smoothness of operation. The Vulcan 1000C leverages a Hypertherm plasma torch and Power-MAX1000 power unit. As such, the Vulcan 1000C can achieve traverse speeds of 25.4m/min。All to the tightest tolerances with no additional edge preparation. The Vulcan 1000C can also be coil fed with either a two or four coil system for the highest levels of productivity.

Revolutionary LCD Touch Screen Control

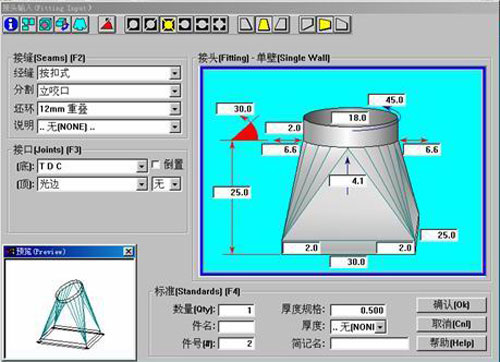

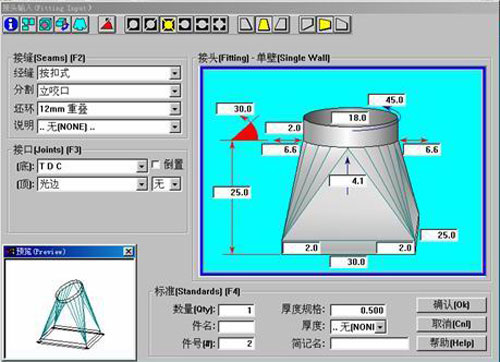

The Vulcan1000C features a 15" LCD touch screen as standard. Now operators can input fittings at the machine by simply pulling up menus and touching the screen. Alternatively, fittings can be sent to the machine from connected

- computers located in nearby offices.

- Industrial-grade color-touch screen

- Manual speed increase/decrease override

- Kerf compensation from 0.001 to 0.999

- Graphic machine status display

- Scale up/down

- Part rotation

- Shape repeat

- Auto home sense to set 0/0 automatically

- 2nd home set for piece work

- Acceleration control

- Automatic corner slowdown

- 40X CD-ROM

- Encoder feedback for positioning

- 80 volt DC power supply 20 AMP

- Remote safety stop switches and current limiting drives for safety

| Feature Summery |

|

- User-friendly operator controls and easy-to-use software

- Excellent cut-quality and precision on a wide variety of materials

- Patented Hypertherm-shielded nozzle for longer nozzle life and heavier piercing capability

- Vertical dual cylinder pneumatic torch lifter with adjustable up/down pressure

- Sealed DC servo motor and motor encoders for steady movement of the torch over the entire cutting area

- Exclusive Gullwing scrubbing action airfoil table eliminates dust particles, on the underside of the sheet metal for clean, square, dross-free cuts

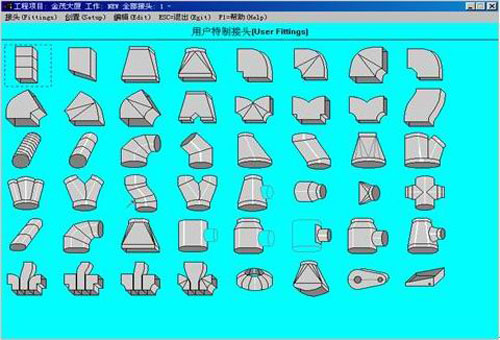

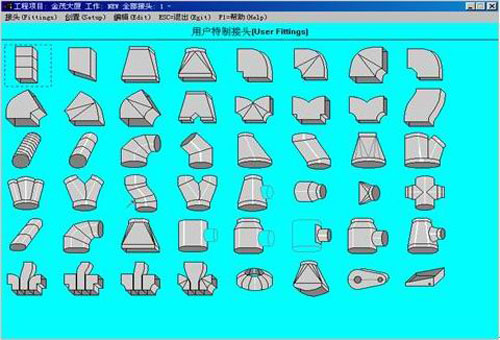

- Pre-designed shapes plus more than 900 icon choices provided as standard

- Preview fittings in 3-D and store frequently used fittings in a user-defined library Welded tubular steel frame

- 3”/75 mm diameter, turned ground & polished y-axis guide rail

- THK linear x-axis bearing and way

- Sturdy welded steel table– with adjustability for leveling machine

- Dual adjustable sheet supports

- Premium components and unrivaled build quality for unmatched reliability and long life

- Optional built-in bar code scanner enables fast scanning and inputting of job data at the machine

|

|

Enhanced Software & Increased Functionality

The Vulcan 1000C fearures the very lates software for maximum efficiency and reliability. Each system includes Lockformer's enhanced fitting cutting software and new supernet optimization program as standard. Live on-line customer support via the Internet is also included.

Preview Softwar – Shows an input fitting as a 3-view picture. Each view can be rotated at any angle to show a full 3-dimensional view of the fitting.

Hole-Cutting Program -- Permits graphic definition of up to eight holes on most rectangular fittings. The holes can be rectangular, round or flat oval, and can be defined at any angle to the horizontal.

Calculation and Cutting of Turning Vanes – Also includes holes for rivets to hold the turning vanes on elbows and T-pieces.

Vulcan Parts Graphic Software – Create and store shapes with a mouse-driven, pop-down menu. This program can hold 10,000 individual shapes, as well as 10,000 sheet jobs at any one time. The software includes a Direct Exchange Format (DXF) transfer program for use with CAD systems.

Background Processing – Allows processing an order or job in the background while the operator continues to input data for a new order.

Accessory Takeoff – Automates the check listing of non-fitting purchased accessory items for each job.

Manual Optimization – Enables the operator to either drag or rotate parts on the processed sheet or move them to da different sheet.

Standard Super Segmenting Program – Splits oversize blanks up to 100 times in each axis.

Standard Manual Segmenting Program – Permits manually controlled segmenting of oversize blanks.

Create fittings with the user-defined library

Vulcan1000C Specifications

1.Computer System

Microsoft Windows Operating System

Multi-tasking 586 office computer

Two high-speed graphic printers with tractor feed for labels

17” SVGA color monitor

1 serial port

2 parallel ports

200' Ethernet Cable

2.Cutting Table

Maximum sheet thickness : 12.7mm

Maximum sheet size : 1500mm x 3000 mm

Maximum weight : 450kg

Cutting speed : 1~25.4M/min, depending on sheet metal thickness

Maximum positioning speed : 25.4M/min

Pierce : 12.7mm

3.Power Source

Adjustable from 20 to 60 amps

40 amp at 100% duty cycle

208/440, 380/575, 60/50 Hz power units available

4.Electrical Requirements

Plasma transformer : 380/3/50 - 30 A

CNC control : 220/1/50 - 15 A

5.Air Requirements

Flux : 320 cf/hour (0.15 cm/min)

Tension : 90 PSI

6.Vulcan1000C Dimensions

Height : 1478mm Length : 4166mm Width : 2058mm Weight : 1215kg

Cutting Speeds Reference

Material

|

Thickness (mm)

|

Power (amp.) |

Cutting Speed (mm/min) |

| Low Carbon Steel |

0.6

2.7

6

10

16

22 |

20

35

55

55

55

55 |

12,446

3,556

1,905

889

406

229 |

| Aluminium Plate |

0.8

3.2

6

10

16 |

20

35

55

55

55 |

11,430

4,064

3,429

1,397

762 |

| Stainless Steel |

0.6

3.2

6

10

16

22 |

20

55

55

55

55

55 |

10,922

3,556

1,397

711

279

178 |

|